Unlocking Efficiency and Longevity in Your Asphalt Maintenance Equipment

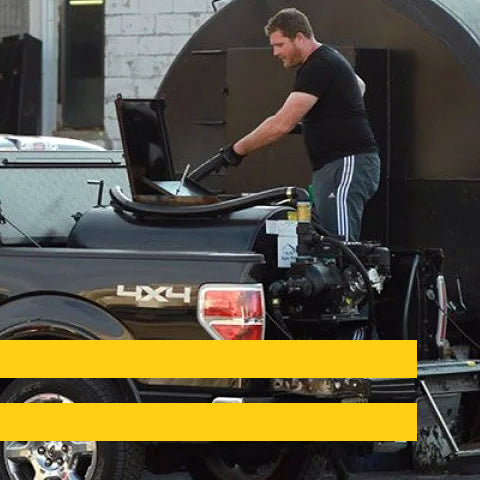

The maintenance and operation of sealcoat spray systems are pivotal in the world of asphalt maintenance. In this guide, we delve into the critical process of priming these systems, a step often overlooked yet essential for their efficient functionality. Priming not only enhances the performance of the spray systems but also extends their lifespan by preventing clogging and other mechanical issues. Let's take a look at how to properly prime a sealcoat spray system.

The Importance of Priming in Sealcoating

Priming is akin to a warm-up for your sealcoat spray system. This process readies the pump and hoses, ensuring a smooth and consistent flow of sealcoat material. It's vital for preventing air locks in the pump, which can lead to uneven spray patterns or even damage to the system. Additionally, priming helps to mix the sealcoat thoroughly, crucial for a uniform application on surfaces.

How to Prime Different Sealcoat Spray Systems

Drum Spray System

- Mixing the Drum: Before immersing the barrel kit in the sealer liquid, thoroughly mix the contents of your drum. Use tools like a Drill Mixer, a paddle, or a paint mixer to ensure the drum contents are fully liquefied, avoiding a thick, sludgy consistency.

- Connecting the System: Place your barrel kit in a 55-gallon drum sealer sprayer or similar sealer source. Connect the suction feed hose from the side of your pump to the barrel kit. Attach the return feed hose from the top of the pump to the top of the barrel kit, ensuring it's submerged in the liquid.

- Prepping the Pump: Verify the oil level in the engine and confirm there's gasoline. Remove the orifice cap on your pump, fill it with a gallon of water, and then reseal it. Ensure the valve atop the pump is set to 'recirculation mode' for effective sealer suction and return through the pump.

- Starting the Process: With the valve in 'recirculation mode', ignite the engine and maximize the throttle. Listen for the pump's hum to deepen, indicating full engagement and the start of sealer recirculation and pump priming.

Tote Spray System

- Connecting to the Tote: Replace the barrel kit with a tote sealer sprayer. Connect the suction feed from the tote to the pump side and the return feed from the pump top to the tote top.

- Pump and Engine Preparation: Remove the pump cap, fill with water, and ensure the engine has oil and gasoline. Start the engine, set the machine to 'recirculation mode', and fully engage the throttle. This system's functionality mirrors others, with one suction and one output port on the pump, requiring 'recirculation position' for priming.

Residential Spray System

- System Connections: Ensure the suction feed is connected to your tank with the valve open. Set the pump's top valve to 'recirculation position' for returning sealer to the AK130 Residential Spray System top.

- Pump and Engine Activation: Fill the pump with water, throttle up the unit, and commence priming. This process ensures efficient system operation for residential spray tasks.

Conclusion

As we conclude our comprehensive guide on priming sealcoat spray systems, it's clear that the meticulous process of priming is a cornerstone in maintaining the efficiency and longevity of your asphalt maintenance equipment. From the detailed steps of preparing the Drum, Tote, and Residential Spray Systems, to the careful execution of priming procedures, each aspect plays a pivotal role in ensuring a seamless and effective operation.

This guide not only equips you with the technical know-how but also underscores the importance of routine maintenance for optimal performance. Remember, a well-primed system is the key to a successful and enduring asphalt application.