What is Bitumen? Here's Everything You Need to Know

Bitumen is the unsung hero of infrastructure, a black, viscous material crucial for paving roads and waterproofing. If you’ve ever wondered ‘what is bitumen?’ it’s essentially the glue in asphalt and the shield on rooftops. This article unfurls the story of bitumen, from its origins and characteristics to its indispensable applications in construction.

Key Takeaways

- Bitumen is a versatile construction material derived from petroleum with applications in road paving and waterproofing, praised for its adhesive and temperature-resistant properties.

- The Athabasca oil sands in Canada are pivotal in global bitumen production, where bitumen’s extraction and processing contribute significantly to the country’s economy and highlight environmental challenges and sustainability efforts.

- Technological advancements have led to innovations such as Polymer Modified Bitumen, Oxidized Bitumen, and Bitumen Emulsions, improving bitumen’s performance and environmental footprint.

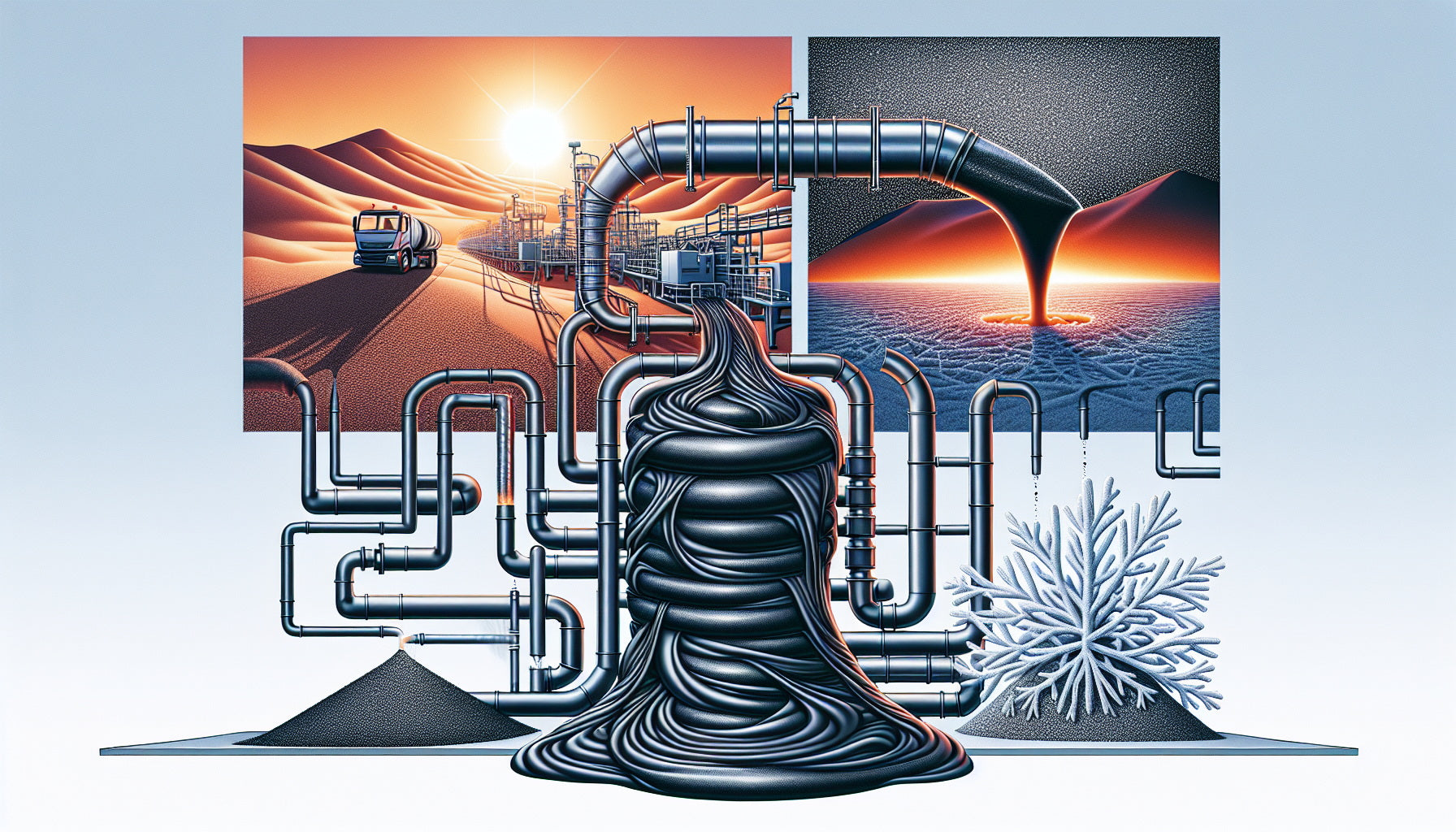

Bitumen Defined: Nature's Black Gold

Bitumen, known for its sticky and highly viscous properties, exists in a semi-solid or liquid form. This black substance is obtained from petroleum and has a complex composition of hydrocarbons that includes asphaltenes and resins. To these components, bitumen contains small quantities of elements like sulfur, nitrogen, oxygen, and various metals. The origin of the word ‘bitumen’ can be traced back to ancient Sanskrit words for pitch, which reflect its longstanding use.

In construction applications where adhesive qualities are essential—especially with regard to temperature fluctuations—bitumen stands out as an indispensable material. Its primary role is in road construction where it serves as a key component for surfacing roads but also acts as an effective waterproofing agent sealing our buildings from moisture penetration. Thus bitumen plays an integral part behind the scenes supporting modern infrastructure by facilitating safe travel on paved surfaces while also preserving the integrity of our building envelopes against water damage.

The Birth of Bitumen: From Organic Materials to Paving Substance

Originating deep beneath the Earth’s surface in areas unexposed to light for eons, bitumen is found both as a natural substance and as a derivative of refining crude oil. Regardless of the extraction method, the resultant material is identical. The formation of naturally occurring deposits of bitumen can be traced back to prehistoric microscopic algae and other small organisms that underwent transformation through intense heat and pressure while entombed within the earth.

Deposits from ancient aquatic vegetation and microorganisms accumulated on prehistoric seabeds, along with lake or river sediments. Over millennia, these organic layers morphed into kerogen before metamorphosing into hydrocarbons due to geological heat and compression forces. It’s these very hydrocarbons that form the fundamental components of crude oil and bitumen alike. When it comes to refining crude oil, bitumen emerges during distillation as one distinct byproduct — characterized by its density at being among the heaviest fractions extracted.

This thick viscous material ascends from subterranean origins to become an integral part of our contemporary lives. All derived from processes taking place over vast spans unseen beneath us.

Crude Oil's Role in Bitumen Formation

Crude oil is pivotal in the creation of bitumen, with refined bitumen emerging through the distillation of crude oil. The processing method involved transforms raw crude oil into a highly versatile and industrially valuable form of bitumen. This production process ensures that unrefined crude is converted to serve multiple applications across different sectors.

The Journey from Natural Deposits to Construction Material

Nature has bestowed us abundant reserves of natural bitumen, prominently exemplified by the vast Athabasca oil sands in Canada – home to the most extensive deposit of this substance. Extracted and refined from these sources, natural bitumen is subsequently converted into an essential construction material extensively utilized for road surfacing and building waterproofing applications.

Bitumen Occurs: From Geological Phenomenon to Industry Staple

Various global sites, including Canada, the United States, Venezuela, Russia, Kazakhstan and Albania, are home to native bitumen deposits. In Albania in particular, there is a type of naturally occurring solid hydrocarbon bitumen called Selenizza.

From historical times onward, the natural bonding and water-resistant properties of bitumen have been harnessed for connecting building materials together and waterproofing the hulls of ships. This underlines its significant role in primitive construction efforts as well as nautical ventures.

Bitumen in Action: Road Construction and Beyond

Bitumen is commonly incorporated into the creation of asphalt concrete, which stands as the primary substance utilized for paving roads. Due to its:

- long-lasting nature

- ability to repel water

- sticky quality

- pliability

- capability to withstand various temperatures

Bitumen emerges as a perfect choice for constructing roadways. The grades of bitumen most frequently employed in roadway construction are 60/70 and 80/100 penetration grades. These figures indicate how soft or hard the bitumen will be when used on roads.

Yet, bitumen’s application extends well beyond just road surfaces. It is favored in car parks because of its impressive adhesive characteristics coupled with its resilience against both water and oil spills. It acts as an effective waterproofing medium on flat roofs, ensuring reliable protection from moisture ingress. The utility of bituminous material indeed spans a wide range of construction needs due to its unique properties that suit multiple contexts within this field.

Asphalt Binder: The Glue of Roadways

Bitumen, often referred to as asphalt bitumen, is essential as a binding agent in the formulation of asphalt concrete used for paving roads. The standard mixture for this type of pavement typically includes about 5% bitumen—also known colloquially as asphalt cement—and 95% aggregates like stone, sand, and gravel. Such a combination lays the groundwork for robust road surfaces by effectively holding these materials together.

The sticky nature of bitumen is what provides our roadways with their ability to withstand significant traffic loads and extreme weather conditions without coming apart. This ensures that they remain cohesive over time.

Waterproofing Qualities: Keeping Buildings Dry

In the roofing industry, bitumen is highly prized for its robust waterproofing capabilities. It’s often used in the creation of roofing felt as well as sealing flat roofs, demonstrating its adaptability with different roofing materials. Bitumen’s superior ability to prevent water penetration makes it a go-to choice for creating an impervious barrier atop buildings.

The sticky properties of bitumen are crucial for fusing together various elements within roofing systems, reinforcing their overall strength and resilience. As such, bitumen plays a vital role in protecting structures from moisture infiltration by enhancing roof durability.

Beyond Pavement and Roofing: Versatile Uses of Bitumen

The uses of bitumen extend well beyond its common roles in paving and roof construction. In the realm of photography, it holds a significant place as Joseph Nicéphore Niépce harnessed a bitumen-based method to create the earliest known photograph. Natural bitumen has been integral for Indigenous populations like the Canadian First Nations who employed it to waterproof their canoes.

Bitumen’s diverse applications are evident throughout various eras and civilizations, demonstrating that its utility spans more than just conventional building purposes. This substance exhibits multifaceted characteristics that have been recognized and exploited far outside typical construction contexts.

Innovations in Bitumen Processing: Refined, Modified, and Emulsified Forms

Technological progress in the processing of bitumen has led to innovative products such as Polymer Modified Bitumen (PMB), Oxidized Bitumen, and Bitumen Emulsions. PMB’s performance is significantly enhanced by employing nanotechnology with additives like nano-silica and carbon nanotubes, which increase its durability, flexibility, and resistance to distortion. Innovations include self-healing PMBs that can spontaneously repair small cracks thereby greatly extending road surface life.

With a focus on stability and endurance, oxidized bitumen stands out due to its reduced penetrability yet heightened softening point along with greater deformation resistance. Through the process of air-blowing into penetration grade bitumen under heat conditions, results in changed physical characteristics tailored for diverse industrial applications.

Bituminous emulsions consist of fine droplets of bitumens dispersed within water using surfactants or emulsifiers to ensure stability. They are primarily used in processes such as tack coats or chip seals among other surface treatment techniques. The influence exerted by emulsifiers extends beyond merely reducing interfacial tension but also includes managing essential properties like viscosity stabilization while promoting adherence between the mixtures constituents, notably aggregate particles.

Polymer Modified Bitumen: Enhanced Performance for Extreme Conditions

Incorporating polymers like styrene-butadiene-styrene (SBS) or ethylene-vinyl acetate (EVA), Polymer Modified Bitumen (PMB) enhances the conventional bitumen mix. This specialized bitumen variant exhibits superior qualities compared to traditional bitumen, including increased elasticity, enhanced rutting resistance, and improved fatigue endurance.

Adapted for extreme weather conditions, PMB excels in maintaining its integrity both in hot environments and under cold climate’s demands by resisting low-temperature fissures effectively. Its robustness makes it ideal for use in areas subjected to intense stress, such as intersections, bus lanes, and airport tarmacs. The result is road surfaces that endure longer with less need for upkeep.

Oxidized Bitumen: A Stable Choice for Industrial Needs

New processing methods are currently being examined to augment the stability and robustness of oxidized bitumen, making it an even better option for industrial uses.

The production technique used to create oxidized bitumen involves injecting hot air into penetration grade bitumen. This modification in its physical characteristics renders it more adaptable for a range of industrial applications.

Bitumen Emulsions: A Greener Approach to Asphalt Application

A vital element within bitumen emulsions is the bitumen emulsion itself, representing a more eco-conscious method for applying asphalt. This mixture consists of fine droplets of bitumen dispersed in water with the help of stabilizing agents and emulsifiers, offering an environmentally sound substitute to the conventional use of hot bitumen by diminishing heat usage and associated energy consumption.

In particular paving and roofing scenarios, utilizing these bitumen emulsions has been shown to be beneficial. They foster sustainability while maintaining performance standards in construction processes that typically employ asphalt products.

Canada's Oil Sands: A Closer Look at Bitumen Production

The Athabasca oil sands, located in Canada, are a pivotal contributor to the production of bitumen on a global scale. Possessing the majority of natural bitumen reserves worldwide, these expansive oil sands cover an area close to 142,000 square kilometers. When it comes to extracting this valuable resource from the Athabasca deposits, nearly 50% is produced using in-situ techniques while surface mining accounts for the other half. After its extraction from beneath Earth’s surface and before being shipped off for processing steps such as dilution or upgrading into lighter forms like synthetic crude oil.

Before transportation can occur for refining processes, it’s crucial that raw extracted bitumen be diluted with condensate or processed through upgrades transforming it into more fluid hydrocarbons akin to synthetic crude oil. The prominence of Canada’s oil sands extends significantly since they contribute approximately ten percent to world-wide petroleum reserves and consist practically entirely (96%) of Canadian total reserves. Within them lays around 161 billion barrels worth of accessible resources, according to estimates centered on the prolific Athabasca region alone.

As recent as 2022 figures denote new records where daily output reached heights never seen at about three point two million barrels – marking extraordinary ascendancy considering this number represents over seventy percentage points out all national extractions during said year thus underlining their enormous importance not just domestically but internationally when discussing volume considerations tied closely alongside topics involving both conventional crudes oils along side wider discussions pertinent toward global productions spanning across various locations entailing naturally occurring viscous substances referred collectively by many experts simply as ‘bitumens’.

Environmental and Economic Aspects of Bitumen

The impact of bitumen on the economy and environment is considerable. Economically, it’s important to note that:

- Bitumen constitutes approximately 4 to 5 percent of the pavement mixture.

- It is considered as the costliest component within road paving materials.

- There has been a significant rise in its price since the turn of the century.

- The pricing patterns for bitumen are closely tied to international crude oil prices and are also affected by market supply and demand.

Environmentally, bitumen presents various challenges due to its effects on air quality, energy use, and waste production. Nevertheless, advancements such as Warm Mix Asphalt (WMA) have emerged as an eco-friendly alternative. WMA reduces production temperatures, which leads to lower energy demands while simultaneously cutting down emissions related to greenhouse gases and volatile organic compounds.

Bitumen's Economic Footprint: Pricing and Demand Dynamics

The economic impact of bitumen is substantial. From the early 2000s through to 2020, there has been a consistent uptick in bitumen consumption annually, with usage approaching approximately 100 million barrels each year. The fluctuating prices of bitumen introduce market uncertainties that can greatly influence the pricing of construction materials. Initiatives focused on recycling serve as strategic measures to mitigate the effects caused by swings in crude oil prices and lend some cost stability within new production ventures for this industry.

A significant portion of global bitumen reserves are located within Canada’s Tar Sands, which underscores a reliance on this particular region when it comes to producing bitumen.

Bitumen and the Environment: Challenges and Solutions

Although bitumen is highly valued for its diverse applications, it poses significant environmental challenges. In a 2020 study, scientists identified bitumen as a substantial source of urban air pollution, especially noticeable during periods of high temperatures and ample sunlight. Bitumen emissions from paving with asphalt—a primary use of the substance—have led to their categorization by the International Agency for Research on Cancer (IARC) as Class 2B possible carcinogens due to the hazardous fumes released.

Problems also arise when using bitumen as an impermeable layer in storing radioactive waste. It can undergo swelling caused by radiation and moisture exposure. There are potential fire hazards at facilities where materials are processed into bituminized form and concerns regarding long-term integrity under geological disposal conditions have been raised. Despite these issues, advancements such as Warm Mix Asphalt (WMA) technology demonstrate promise toward mitigating environmental impacts since they enable lower production temperatures that subsequently cut down both energy usage and greenhouse gas along with volatile organic compounds emissions.

Recycling and Sustainability in the Bitumen Industry

The bitumen industry is advancing in its efforts to promote sustainability through recycling programs. In the realm of construction, reclaimed asphalt pavement (RAP) and reclaimed asphalt shingles (RAS) are among the foremost recycled bitumen-containing materials contributing to eco-friendly practices. The material removed from worn-out asphalt pavements during repairs can be collected, taken back to production facilities, and reincorporated into fresh mixtures for paving purposes—this process effectively recycles the bitumen content.

Adopting recycled asphalt yields multiple advantages.

- It helps preserve finite resources.

- It diminishes the ecological footprint associated with building activities.

- It considerably cuts down on waste generation and carbon emissions.

- It propels the construction sector toward greater sustainability and environmental consideration.

- This approach reflects a deep-seated commitment by those within this field to minimize their impact on nature while upholding product integrity as well as performance standards.

Reclaimed Asphalt Pavement: A Circular Economy Model

Reclaimed asphalt pavement (RAP) exemplifies the circular economy concept within the bitumen sector. It is produced by extracting and pulverizing current asphalt, subsequently integrating it into fresh mixes for new pavements. This practice conserves considerable energy as it curtails the necessity to produce virgin bitumen and aggregates.

Incorporating RAP significantly slashes the quantity of construction debris relegated to dumps, thus promoting waste minimization and protecting our natural surroundings. From an economic perspective, employing RAP cuts down on material expenses because it reduces reliance on newly sourced raw materials, rendering a more economically efficient alternative in creating asphalt road surfaces.

Reclaimed Asphalt Shingles: Extending the Life of Roofing Materials

The bitumen industry benefits from sustainability efforts through the use of Reclaimed Asphalt Shingles (RAS). These shingles are essentially waste material collected from roofing projects, such as replacements and renovations. Once collected, RAS is repurposed across different uses by recycling it. The procedure includes pulverizing the discarded asphalt shingles into a granular form that can be incorporated with fresh materials to produce superior roofing solutions.

Recycling Reclaimed Asphalt Shingles not only enhances the durability of new asphalt-based products, but also minimizes landfill accumulation and encourages resourceful utilization within the industry.

Kevin King's Expert Insight on Bitumen Applications

Kevin King, the founder and premier blog contributor at Asphalt Industrial, provides valuable knowledge regarding the utilization of bitumen in various contexts. Possessing extensive experience within the industry, King discusses not only asphalt upkeep methods but also handpicks top-notch asphalt maintenance machinery available for purchase. He is committed to enhancing consumer shopping experiences by ensuring that his platform offers straightforward functionality coupled with high-caliber merchandise at fair prices.

King imparts actionable guidance which proves beneficial for effective conservation and deployment of bitumen in diverse construction environments. His proficiency and deep insights contribute significantly to expanding our comprehension of both bitumen’s practical applications as well as its critical role in everyday infrastructure projects.

Summary

Emerging from beneath the Earth’s surface to become a cornerstone of the infrastructure we rely on daily, bitumen’s role is both intriguing and indispensable. This viscous black substance, also known as nature’s own precious “black gold,” is critical for various aspects of modern construction. It has proven itself time and again with its application diversity ranging from providing smooth pavements in road construction to ensuring waterproof shelters through roofing materials.

In an ongoing quest towards eco-friendliness within the industry, recycling measures are actively enhancing sustainability efforts by reducing environmental strain. Advancements have been made in refining bitumen leading to innovative products such as Polymer Modified Bitumen, Oxidized Bitumen, and Bitumen Emulsions. All geared toward improved performance while being more ecologically considerate alternatives. The saga of bitumen serves not only as a reflection of human creativity but also our capacity to adapt natural resources for collective advancement—it serves as a humble reminder that oftentimes it’s what sits quietly below our feet or guards us overhead that significantly enriches our lives without fanfare or notice.

Frequently Asked Questions

What is bitumen used for?

In the construction sector, bitumen serves a crucial role as an adhesive and waterproofing agent, especially valued for its application in paving roads, runways, footpaths and parking lots. It’s also integral to roofing applications due to these properties. As a binder mixed with asphalt for various infrastructure projects, it ensures durability and longevity.

What is bitumen in the Bible?

In the Bible, bitumen is mentioned as a dark and viscous material applied for water resistance purposes, evident in its use during the building of Noah’s ark and also in sealing Moses’ bulrush basket.

What is the difference between asphalt and bitumen?

Bitumen, a material composed of hydrocarbons that occurs naturally, is distinct from asphalt in that asphalt represents an engineered product created using bitumen as its base.

Is bitumen the same as tar?

No, tar and bitumen are distinct substances. Bitumen is derived from petroleum processing, whereas tar occurs naturally from materials such as coal, wood or peat. Tar possesses unique characteristics when compared to bitumen. It melts at an elevated temperature and contains a greater amount of carbon.

How is bitumen produced?

Bitumen is produced by distilling crude oil or can be found in natural deposits.