Concrete vs Asphalt Roads: An Unbiased Comparison of Durability and Cost

Deciding on concrete vs asphalt roads is a pivotal choice with long-term implications for cost, maintenance, and performance. Our comparison gives you the essential insight into each material’s pros and cons, focusing on how they stand up to traffic, the elements, and the test of time. By the end of this article, you’ll have a clearer idea of which pavement option aligns with your specific needs, budget, and environmental considerations.

Key Takeaways

- Concrete roads last longer with a service life of 20-40 years and tend to require less frequent maintenance, but often come with higher initial costs compared to asphalt roads.

- Asphalt roads offer advantages like lower initial construction costs, ease of repair, and superior traction in snowy or wet conditions, but typically have a shorter lifespan and require more frequent resurfacing or repairs.

- Environmental considerations play a role in decision-making, with asphalt production contributing to CO2 emissions and pollution, while concrete roads can absorb CO2 and have lower life cycle costs, particularly in areas with heavy traffic.

Quick Comparison: Concrete vs Asphalt Roads

Concrete roads are renowned for their longevity and eco-friendliness, making them a superior option for building long-lasting roadways. The advantages of using concrete in road construction are derived from its rigid nature that resists deformation even under the stress of heavy traffic loads. These types of roads can absorb carbon dioxide, which could offset some emissions associated with cement production.

On the other hand, asphalt roads come with their own set of benefits, including being more economical to build. They also promote safety during winter weather conditions or when there’s a high risk of skidding due to their inherent flexibility which helps prevent cracking caused by fluctuations in temperature. The dark hue of asphalt provides increased visibility for lane markings under adverse weather conditions like rain or fog.

The Composition of Road Surfaces

Asphalt roads and concrete roads are distinguished by their core compositions. A combination of aggregate materials, cement, water, and occasionally steel for additional reinforcement forms the basis of concrete roads. In contrast, asphalt roads rely on an amalgamation where bitumen acts as the binding agent alongside the primary component – aggregate.

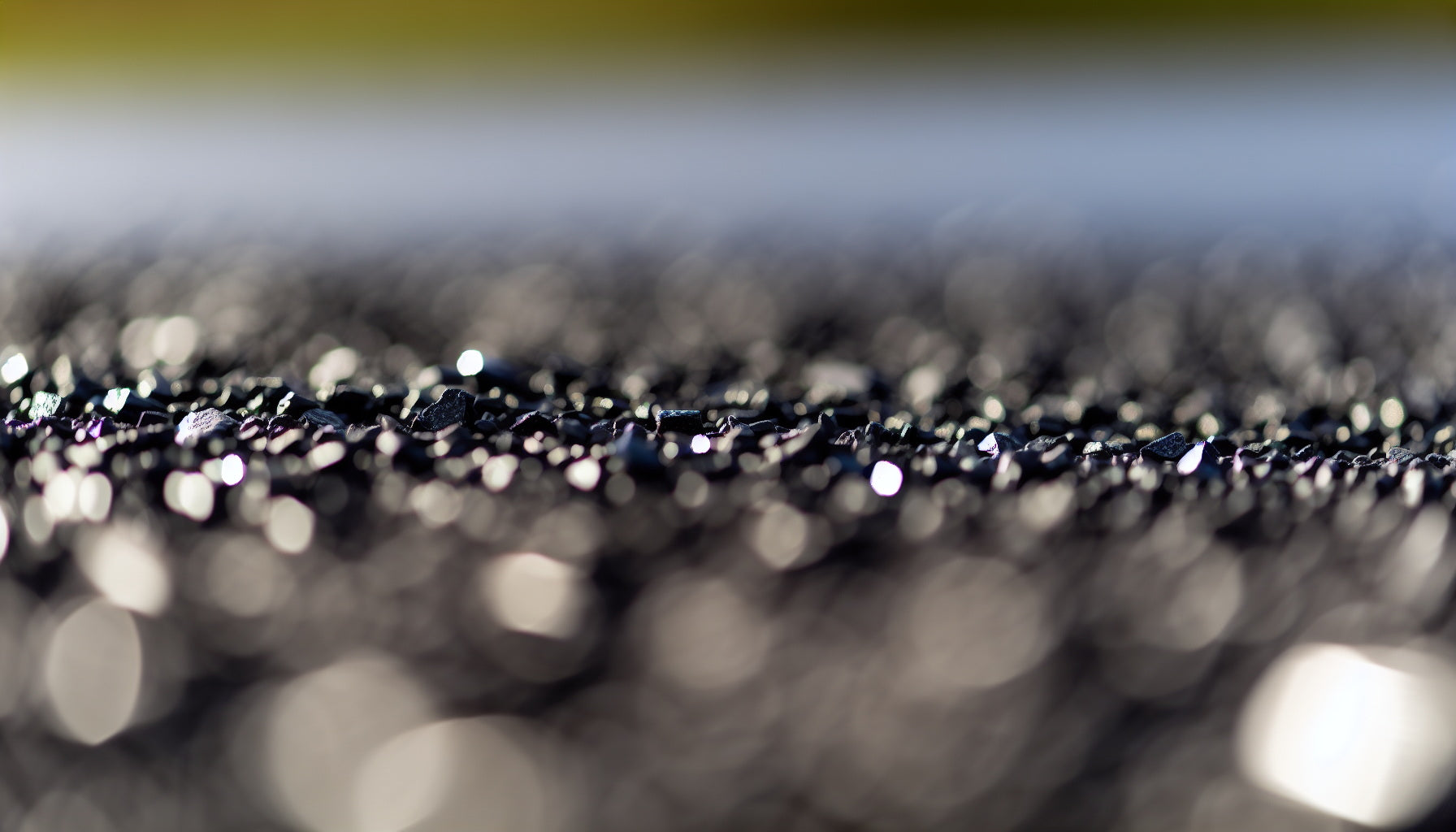

Breaking Down Asphalt Pavement

Essentially, an asphalt mixture is comprised of a blend of aggregate and binder, with the mix Including approximately 84 to 90% aggregate, between 6 to 12% asphalt binder, and roughly 4% air voids by volume. The role of the bitumen as a binding agent in these mixtures is crucial. It adheres to the aggregates creating a sturdy surface suitable for roads.

The quality assessment of an asphalt mixture hinges on its specific gravity and effective content of asphalt. A critical aspect in assessing these properties is determining the theoretical maximum specific gravity—representing how dense the mixture can be without any air voids—which greatly influences volumetric characteristics such as percentage levels concerning both air voids and mineral aggregate void spaces within that given mixture.

Understanding Concrete Slab Construction

In the construction of concrete roads, a mixture comprising cement, water, fine aggregate, coarse aggregate like crushed rock and sometimes chemical admixtures is utilized to produce finished concrete. The cement acts as a binding agent that solidifies and connects the different aggregates forming durable pavement with substantial rigidity.

Concrete slabs used in road construction are formulated with precision to strike an equilibrium between their strength attributes and ease of handling during construction. Concrete destined for high durability in freeze-thaw conditions is crafted with minimum permeability and optimal air conditioning to withstand 4,000 psi or higher.

Durability and Service Life: A Core Concern

Concrete roads excel in longevity and robustness, boasting a serviceable life of 20 to 40 years, which can outlast asphalt roads by up to double their lifespan. This extended durability means less frequent need for replacement. The resilience of concrete makes it better suited for areas with heavy truck traffic because it doesn’t easily sink or develop ruts. It’s particularly advantageous on highways and at junctions like bus stops and intersections where its ability to withstand fluid leaks from vehicles as well as the stress caused by vehicular start-stop actions is beneficial.

Asphalt roads have an advantage in their capacity to resist temperature-induced cracking due to their elastic nature. Yet, certain variables such as air void content within the material, thickness of binder film covering aggregate particles and the total amount of asphalt binder used may negatively affect road performance over time—leading potentially not only towards rut formation but also towards increasing fragility under environmental pressures that include instances where melting asphalt becomes problematic.

Maintenance and Upkeep: Balancing Costs and Effort

When comparing asphalt to concrete roads, maintenance considerations play a significant role. Concrete roads tend not to need as much upkeep as their asphalt counterparts and can be more economically advantageous in the long term due to this reduced frequency of maintenance, despite higher initial installation costs. In environments with heavy traffic loads, concrete’s lifecycle cost—roughly 20-25% less than that of asphalt—is particularly attractive for its potential savings.

On the other side of the spectrum lies asphalt pavement, which offers ease in performing small-scale repairs quickly and inexpensively. Such patching is less intensive both in terms of labor and expense when contrasted with the full pavement replacement often necessary for concrete surfaces. Despite these advantages during minor fixes, frequent resurfacing or reparative work might be necessitated by asphalt’s lower longevity—a factor making paving method selection critical from a durability standpoint.

Environmental Considerations in Paving

The selection process between concrete and asphalt for roads heavily factors in the impact on the environment. Producing asphalt is associated with CO2 emissions, stemming from heating and combining petroleum-based substances that make up asphalt. Throughout its production and recycling lifecycle, asphalt releases greenhouse gases into the atmosphere, leading to incremental environmental costs. Asphalt pavement also poses ecological concerns as it can contaminate soil and groundwater due to its inability to degrade while releasing harmful emissions during the paving process.

Conversely, when producing concrete, there is comparatively less pollution involved and it utilizes limestone, which is plentiful. Not only does this make concrete a more eco-friendly option, but through carbonation – where absorbed CO2 could neutralize approximately 5 percent of cement-related emissions – it holds an intrinsic ability for offsetting some of its own environmental tolls. Nevertheless, despite these benefits, one must consider that in areas with higher temperatures, concrete may exacerbate local heat retention issues due to its thermal properties.

Safety and Performance on the Road

Asphalt roads enhance vehicle safety and provide a smoother ride by offering better traction and higher skid resistance compared to their concrete counterparts. The freshness of asphalt ensures a more silent drive when contrasted with the texturing-associated noise generated by aging concrete surfaces.

Conversely, concrete surfaces have an advantage in that they present less rolling resistance due to their smoother texture relative to the coarser surface of asphalt. This lower rolling resistance can lead to an improvement in fuel efficiency ranging from 2-5%, which translates into considerable savings, especially at increased speeds.

Cost Analysis: Initial Investment vs Long-Term Savings

When deciding between asphalt and concrete roads, both upfront and ongoing expenses play a crucial role. The immediate installation expense of asphalt driveways is Lower than that of concrete, with costs ranging from $5 to $15 per square foot for asphalt compared to $8 to $18 for concrete. In fact, research has revealed that on similar roadways, the initial cost involved in constructing an asphalt road can be 10 to 25 percent less expensive than laying down a concrete one.

Despite its steeper introductory price tag, over time concrete might prove more economically sound due to its reduced need for maintenance compared with its asphalt counterpart. Asphalt offers an advantage as it allows resurfacing, which is relatively inexpensive and extends the life of the roadway without necessitating complete removal or replacement. Yet when examining the entire lifespan expenditures inclusive of construction and upkeep costs – referred to as life-cycle costs – routes surfaced with asphalt have often been observed having considerable savings. To those made with concrete. These savings range anywhere from 13 percent up to an impressive 107 percent dependent upon specific route conditions and usage patterns.

Aesthetic and Functional Aspects of Road Surfaces

Selecting between asphalt and concrete for road surfaces often depends on their visual appeal and performance characteristics. The smoothness of an asphalt pavement results in reduced vibration and noise from the surface, making for a more comfortable driving experience. As time passes, these roads preserve their dark hue that may be preferred by certain individuals.

On the other hand, textured concrete roads provide superior traction, which could result in a less smooth drive with increased noise for occupants of vehicles. With age, there’s also the possibility of concrete slabs settling or moving marginally out of place, Diminishing ride comfort and amplifying sounds produced by vehicular traffic.

Adaptability to Traffic and Load: Heavy Trucks and High Volumes

Concrete is frequently selected for roadway construction in locations with significant heavy truck traffic, owing to its ability to withstand high volumes of weighty loads. The resilience and toughness of concrete pavements make them less susceptible to forming ruts and depressions, which explains their popularity in constructing highways exposed to persistent heavy truck traffic.

Conversely, asphalt roads excel across diverse terrains and are typically more economically viable. Nevertheless, cities like Mumbai that experience substantial rainfall favor concrete over asphalt because it offers enhanced performance under wet conditions and exhibits a lower tendency for pothole development.

Case Studies: Real-World Applications

The strategic use of both asphalt and concrete roads can be understood through their real-world applications. In Oregon, USA, Interstate 84 uses asphalt pavement in the left lanes and concrete pavement in the right lanes to accommodate heavy truck traffic. This strategy demonstrates the adaptability of both materials based on load-bearing needs.

In India, cities with high rainfall, like Pune and Mumbai, prefer concrete for roads in areas of heavy rainfall to prevent frequent damage and enhance durability. However, despite criticism over the construction quality of asphalt roads, some Indian municipalities opt for asphalt for its recyclability and smoother ride compared to longer lasting and less maintenance-intensive concrete roads.

The choice between asphalt and concrete also depends on topographic factors. Rural areas with many driveways and rolling terrain often prefer asphalt to concrete due to its cost-effectiveness and practicality for varied topographies. However, in high-traffic areas like the Mumbai-Goa highway in India, high-quality asphalt is preferred for its surface, despite higher associated costs.

Summary

Ultimately, the decision to opt for either asphalt or concrete roads hinges on several considerations such as initial expenditure, longevity, upkeep requirements, ecological footprint, and traffic density. Concrete surfaces boast enduring robustness and a reduced environmental toll. Asphalt surfaces are more economical upfront and afford superior traction under specific circumstances. Evaluating these elements within the unique parameters of an individual project is critical to ensure a judicious choice is made.

To learn more about asphalt, check out this article on asphalt vs. blacktop, or this article that covers what is asphalt in depth.

Frequently Asked Questions

Is asphalt better than concrete for roads?

Concrete roads outperform asphalt ones due to their increased durability and reduced need for maintenance, though they may come with higher repair costs when needed. While asphalt can have a lifespan of up to 18 years, concrete typically endures for about 25 years, potentially reaching 40 years if meticulously maintained. Concrete’s resilience also extends to its ability to bear heavier burdens and resist extreme weather conditions that might cause asphalt to soften.

Nevertheless, the price in both time and money tends to be higher. Be steeper when it comes to mending concrete roadways compared with those paved in asphalt.

What is the main disadvantage of concrete roads?

Asphalt roads tend to outlast concrete roads as the latter are more susceptible to cracking earlier, potentially increasing the risk of accidents.

Heating the mix for concrete demands an extensive amount of energy.

Why are US highways made of concrete?

Approximately 60 percent of the interstate system in urban areas is constructed from concrete due to its superior durability and capacity to bear heavier burdens, making it a material of choice for US highways (Wikipedia).

Why don't we use concrete for roads?

Due to its greater brittleness and tendency to crack, concrete often leads to a less smooth driving experience, which is why it isn’t typically the material of choice for road construction.

In contrast, asphalt offers more flexibility and cost-effectiveness when used in constructing roads.

What are the main differences between asphalt and concrete roads?

To sum up, while asphalt roads offer the benefits of lower cost and superior traction, concrete roads excel in terms of durability and environmental advantages.

Each type presents its own set of pros which means that selecting between asphalt or concrete surfaces should be based on particular requirements and factors.